I received an Express SR for a short period of time and installed the exhaust, carburetor and a few other things to get it to start. My initial impression is that I’ve had a blast riding the Express SR. It has two main advantages over other bikes – it is low to the ground and it is very light. Sitting lower to the ground than most nopeds/mopeds, it gets under the wind and it’s easier to maneuver than it’s less height-challenged brethren. Being lightweight, it’s got less baggage to prevent it from going faster.

If you listen to motorscooterguide.net, you may be tempted to believe that the SR can hit 35-40mph in stock form. Don’t believe it! There’s no chance of that happening. In stock form, it’s lucky to do 30mph. But you can easily increase top speed and acceleration without much difficulty or expense. To increase your top speed on the SR, I recommend the following:

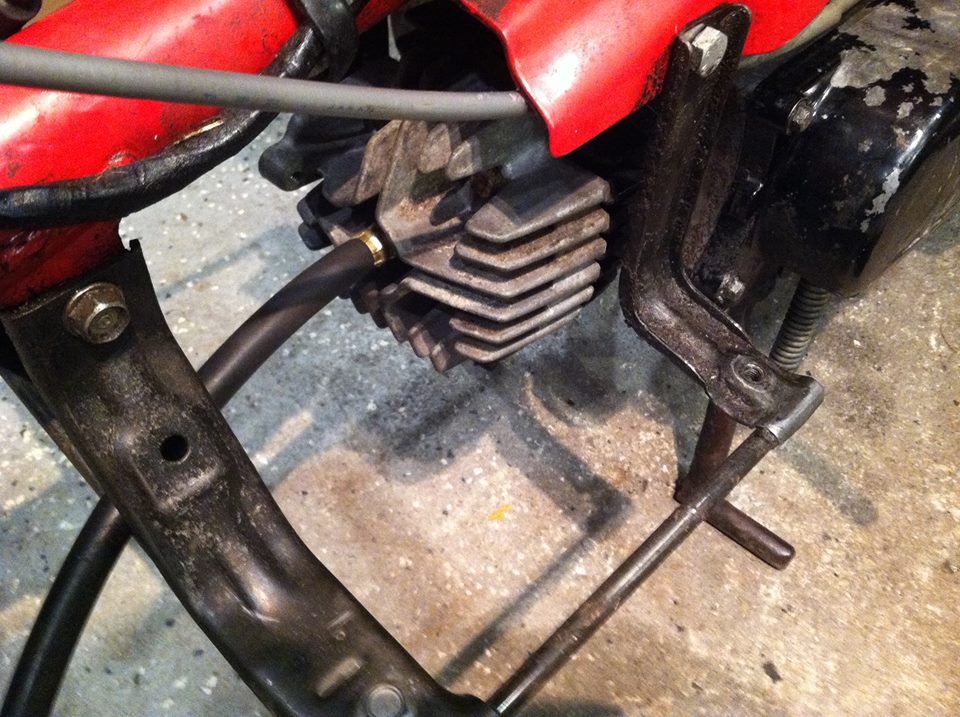

1. Install a performance exhaust pipe. MLM makes a side bleed pipe for the Urban Express and the Express SR. It appears that it will hang pretty low so you may want to go with the biggest rear tire you can find to get it further from the ground. I’ve installed a 3.5″ x 10″ rear with no problem. The bigger tire will slow you down but you may avoid scuffing your new pipe on hard right turns.

A cheaper route would be to hack’n’weld a tomos biturbo to the Honda header. It will sit much higher and you’ll save $100+ for similar performance.

2. Get your jetting right. This is especially important after installing a performance exhaust. Honda typically over-jetted its 50cc 2 stroke bikes. I doubt the SR is any exception. It came with a 65 78 main jet which was undoubtedly too rich for the stock set up. It may be just fine for the addition of a performance exhaust. You will need to determine which main jet is best. The wrong jet can easily rob you of 5 mph or more. You should buy a range of 3-5 main jets (nc50, nu50, and nx50 keihin main jets – same jet for all three bikes) to try. Find that jet that gives you your highest top speed and then install the next larger size. The jets usually run in increments of two.

3. Tune your variator – With just the addition of a performance exhaust, 30 to 33 grams of weight in the variator should get you really close. Tuning your variator involves finding the best combination of weights to get the best acceleration while keeping your top speed. Too little weight will rob you of top speed as the belt will never travel to the top of the variator. Too much weight will kill your acceleration. Experiment until you find the right weight for your particular set up.

4. Change your belt. Chances are your stock belt (if it came with that) has worn over the years from it’s original 0.55″ width. The best substitute I’ve found is the Gates 9290 belt which is 0.5″ wide and almost the same length as the stock belt.

5. Add a GY6 clutch with red 2000k rpm springs to improve your take-off speed. Add a Stage6 MK II clutch and get the red race springs. This is an adjustable clutch and will make a huge difference with initial acceleration.

6. Add a yellow 1500k rpm contra spring for improved performance on hills.

7. Open up the narrow exhaust port on the cylinder. You’ll lose some low end but mid-range acceleration and top speed will be much better. Actually, leave the exhaust port as it is near the header but raise the exhaust port 2mm or so at the cylinder wall.

8. Check and increase your compression if necessary. The manual claims that compression should be 185 psi. If you are much lower, you can install a new piston and rings and hone your cylinder (assuming cylinder is not overly worn). You can also increase compression by sanding the cylinder head flat and running without a head gasket. I go into it further below.

All these changes will run you about $150 $250 with the Stage6 clutch and should get you passed close to the 40mph barrier. There’s obviously much more you can do but this is a good start. I’ve documented my experience below.

My Express SR came with a hack’n’weld pipe, the likes of which I had never seen before. Here’s a video soon after I received it:

I ended up making a tomato can silencer to try to quiet the ridiculously loud pipe. It is still too loud but the silencer made a bigger difference than I thought it would. I had all kinds of trouble with the carb leaking and I wasn’t sure where it was coming from. At different times, I thought it was leaking from the float bowl gasket, the fuel line, the petcock, and perhaps other places. After swapping carbs a couple times and changing the fuel line, I was able to hit on a non-leaky combination. I kept the 78 main jet that came in the original carb but it was running way too rich. I checked the jet size and someone in the past had drilled it out to about a 92 main jet. The stock jet on a Honda Express SR is a 65.

I tried a 65 jet but this was way too lean with the big pipe that was on it. I settled on a 75 main jet for now. I removed half the variator weights (39 grams in variator) and am running the stock belt currently. Here’s a video with this set up. Top speed so far is 33.2 mph.

I’m going to install a different pipe as the current pipe is much too big for the bike. I don’t think the bike makes the rpms to get the pipe to hit right. Ideally, with this setup, 33 or 36 grams in the variator would be better.

I also ordered several belts to try. The stock belt is 14mm wide when new and I have yet to determine its length.

I’m going to try an A28 belt which is 1/2″ thick and 30″ long;

A B26 belt which is 5/8″ thick and 29″ long;

A B27 belt which is 5/8″ thick and 30″ long;

and a Gates 9290 belt which is 1/2″ thick and 29 3/8″ long.

The manual indicates that compression should be 185 psi. Mine measured at 135 psi and I later raised it to 150 psi.

Anyhow, a performance pipe, a proper belt, and some variator and clutch tuning should get it up around 40 mph (as I later found out, getting to 40 mph is pretty hard on the Express SR with the stock cylinder).

I’d like to try a 3.5″ wide rear tire and report on that result as well.

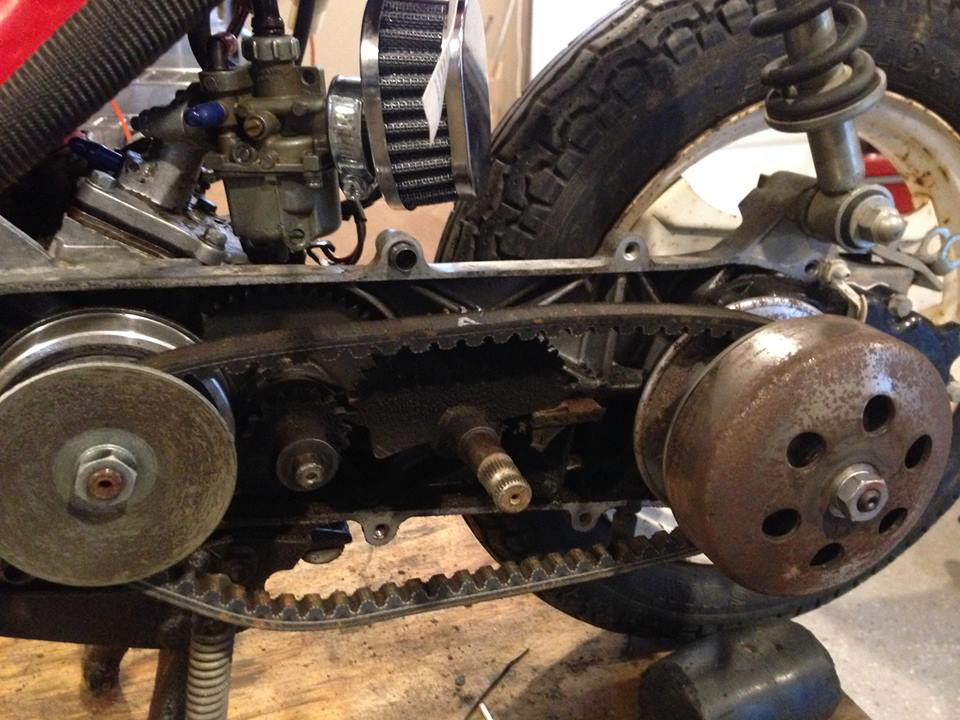

Variator with stock belt. Kick return stop was broken off but doesn’t seem as big a deal as on the Urban Express.

Making a silencer. Step 1 – drill holes in the stinger.

Step 2 – fashion tomato can to act as one end of the silencer.

Step 5 – wrap with furnace tape and add screws.

Here’s the big B pipe in all its glory.

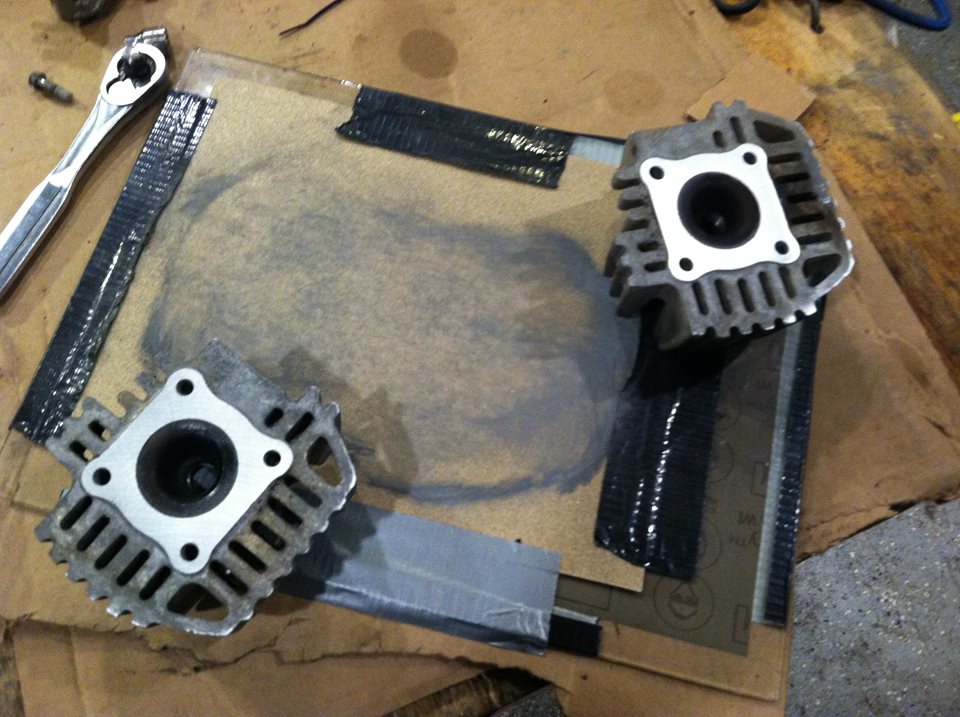

Let’s raise the compression some from current reading of 135 psi.

Tape some 220 grit and 400 grit sandpaper to a piece of glass. Sand in figure eight patterns until cylinder head gasket mating surface is uniformly shiny. You’ll be able to tell when it’s flat this way. Clean off cylinder head of all aluminum dust (wear a dust mask) with paper towels and WD-40 or other cleaner. Keep wiping until paper towel comes back white.

Install head and torque down to proper specs – 7-9 ft/lbs. Test compression by inserting tester end in spark plug hole, screw down hand tight. Kick bike several times with throttle held wide open. Do so until needle no longer moves on gauge.

Head installed and testing compression.

More changes to the Express SR

Here’s my old belt trick – just flip it inside out for higher top speed. Fat side is now on the bottom.

En Fuego Tecno Boss Pipe on the Express Sr now.

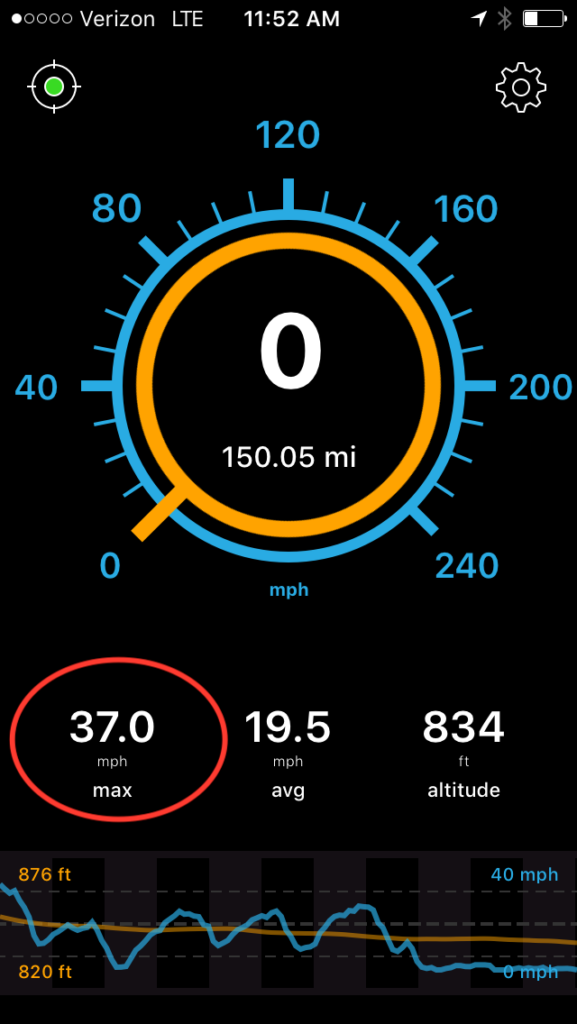

New top speed with Tecno Boss pipe and inside out stock belt. 37 mph.

11/3/2018 update:

The B27 belt I have is just too fat and long for the stock engine. My Express SR ran like a dog with it on, although it’s much quieter now because it can’t rev with that belt on. Maybe the B27 or BX27 belt would work with a bigger top end but it’s too much belt for the stock engine.

So the A28 belt was up next on the testing bench. I flipped it inside out since it was only 1/2″ in diameter. Stock belt is 0.55″ new. I noticed that this belt, since it was new, didn’t really want to stay flipped inside out. I should’ve taken the hint. From a stand still until maybe 10mph, the bike vibrated probably due to the belt trying to twist back to its original orientation. I took some false comfort in the fact that it smoothed out after a certain speed. The belt eventually broke and I assume it was due to some of it twisting back to its original shape and some remaining twisted inside out. I think the belt was too long and too thin anyway (30″ long). Stock belt is 29 1/4″. Doesn’t seem like much of a difference but the new belt was thinner as well. The combination of too thin and too long is not good in this application.

I also forgot about trying to add a washer at the end of the boss with the B27 belt. That would space the front pulley out 1.5mm~ and reduce the belt width to something like 14.4mm which is really close to the stock belt’s 14mm width. Of course, the rear pulley is not affected by the washer on the front pulley so the belt wouldn’t sink as low in the rear as the stock belt. But it should be worth a try.

I should address the claim on the internet that the Honda Express SR’s top speed in stock form was around 35-40mph when new. I’m calling a Big Bullshit on that! It would probably hit 30mph in stock form when new (this write-up makes a more reasonable claim of speeds in excess of 30 mph which could mean 31mph). I know my current compression at 150 psi~ doesn’t compare to a new bike’s alleged 185 psi compression but the stock exhaust, stock carburetor and belt in normal configuration would prevent this bike from hitting 35 or beyond in the real world. Honda typically over-jetted all these 50cc bikes and I don’t see how the Express SR would be any exception. And such over-jetting would severely limit top speed. 185 psi compression wouldn’t help with top speed either. It would probably hurt your top speed.

The article mentioned above recommends a 84290 belt which is 1/2″ diameter and 29″ length so it would be shorter and narrower than stock belt so top speed would definitely be affected.

11/4/2018 update:

I took off 1.3mm from the boss with a belt sander and some hand sanding and tried the stock belt in its normal position. 36 mph. I’ll get the 9290 belt and try it soon.

11/5/2018 update:

Added a GY6 clutch with red springs.

Shortened boss vs. standard boss.

Clutch again.

3.5″ wide tire fits with ease on the Express SR.

11/6/2018 update:

Final word on Honda Express SR performance.

Express SR performance really centers around the drive belt given the lack of an exact replacement stock belt. I should note that all testing was done on a stock bike with a mediocre performance exhaust (tecno boss for a Tomos A35 welded to stock Express header) and 36 grams in the variator using 6 weights. I used the stock carb with a 75 jet and stock cylinder. A completely stock bike (and a more modified bike) will perform differently with my findings. I’ll try to note how, to the extent that I can extrapolate. All other upgrades (e.g., bigger top end, bigger carb, better exhaust, etc.) have already been covered in the Urban Express world and should directly translate to the SR.

I was lucky enough to have a stock belt on my Express SR, and I’ll start out by saying that the easiest upgrade is the ol’ inside out maneuver. Take your stock belt, turn it inside out and install it that way. I achieved my top speed doing this of 37 mph, a gain of almost 4 mph (12%) over my previous base configuration stock speed. I’ve done the same trick on an Urban Express and achieved about the same 4 mph gain. No, the teeth on the belt are not necessary for use in this application, and, no, the belt won’t wear out any faster. One caveat: new belts of this small width (~1/2″) tend to want to twist back to their original configuration. So break your new belt in if you want to try this.

As mentioned above, I bought the following belts:

I’m going to try an A28 belt which is 1/2″ thick and 30″ long;

A B26 belt which is 5/8″ thick and 29″ long;

A B27 belt which is 5/8″ thick and 30″ long;

and a Gates 9290 belt which is 1/2″ thick and 29 3/8″ long.

The B26 and B27 belts were garbage on my configuration. Well, I tried the B27, and it was so abysmal that I didn’t even bother with the B26 (they were both the same width). My bike as configured couldn’t handle the gearing created by that belt. That belt sat too high in both pulleys at take off. RPMs were muted and the belt was too wide to really sink down low enough in the rear pulley. I could’ve tried adding a washer over the crankshaft and between the boss and the outer front pulley to give the belt more room to sink down on that pulley but you still have the problem with the belt and the rear pulley. I never tried it. And given the B27 results, I never tried the B26. Now, a kitted bike might be more successful with that belt especially if a washer were added.

I moved on to the A28 belt which, because of its dimensions, seemed promising. I did this after I had my success running the inside out stock belt, so I naturally decided to try the A28 inside out. As indicated above, this was a mistake with a new belt. Further testing will have to take place upon obtaining another A28.

I received my 9290 belt and tested that last. While I waited for it to arrive, I thought about how to make the 9290 more like the stock belt. I knew that the stock belt was 0.55″ wide (14mm) or 1.3mm wider than the 9290. I came up with sanding the boss down 1.3mm with the help of a belt sander and some finishing touches by hand. At the same time, I received a new 3.5″ wide tire. Ignoring the rule of just changing one thing at a time, I did all three (new belt, shortened boss, and huge tire). By the way, the 3.5″ tire fits easy on the SR. The combination of the three was too tall a gear for the engine to manage well although it did better than the B27 belt experiment. Acceleration was poor and top speed was maybe around 31 or 32 mph. (Now a shortened boss with the 9290 and stock rear tire might have done really well, fyi).

I should mention that I tried the shortened boss with the stock belt (and stock rear tire) in the correct configuration and achieved 36 mph and acceleration didn’t take too much of a hit. I thought that was a very good result.

The bigger rear tire (assuming the engine can turn it at the same rate) should give about 3.32 mph more at top speed (~35mph) than the stock rear tire.

While taking off the 9290 with the intention of trying the stock belt again, I decided to compare the new 9290 belt and the old stock belt. Turns out the old stock belt was worn down and narrower than the new 9290. At this point, I decided to try an original length boss (same as the Urban boss) with the 9290 belt. Results were promising and I may be able to approach the 37 mph mark again. I doubt I’ll better it. Hills seems to be more of a challenge with this configuration although it more readily takes advantage of even the slightest downhill now. I’ll take it for another ride soon.

By the way, the Urban and the SR share the same variator, weights, front pulley, clutch, carb (although jetting is different), intake and possibly more.

Conclusions and where do we go from here.

You can affect gearing in several ways on these bikes: 1) notching or windowing the variator (which I didn’t do); 2) shortening or lengthening the boss; 3) using various belts of different dimensions; 4) changing rear tire size. I think I’ve achieved a good result with the 9290 belt, stock length boss, and 3.5″ rear tire (wider tires are also taller tires hence the effect on gearing). I’d like to experiment more with a boss that is 0.5-1 mm shorter than stock. This change pushed the front pulley cheeks closer together and the belt rides higher. This is all at the cost of some acceleration; however, you may be able offset that with stiffer clutch springs and/or variator weight changes. The boss modification is not as punitive as a belt change because you only affect the front pulley. A wider belt sits higher in both pulleys.

As mentioned above, a shortened boss with the 9290 and stock rear tire might have done really well.

I really need just a little more power out of my engine to exploit these changes. I’d like to keep the cylinder stock so I may experiment with increasing compression further and increasing flow.

11/7/18 update:

Stock belt with wide tire helped with the rpms as it seemed to be revving out much better. I raised compression to 155 psi. I took it over to my friend’s house and on the way, I started to run out of gas. As it leaned out, it really started to rip. I probably need to down-jet a tad.

11/8/18 update – different owner but the quest continues:

The new owner of the bike, a good friend of mine, wants to continue the speed quest on the stock cylinder. Our goal is to get it over 40 mph.

The plan:

1. Put back on old stock rear tire;

2. Flip stock belt inside out – with these two changes we should get back to 37 mph;

2a. Try 9290 belt with shortened bushing to see if we can get more speed than inside-out stock belt;

3. Put on a different carb (revolution carburetor – 14mm) and adjust jetting so that the pipe will hit better (drop down to 70 jet);

4. Get compression back to stock specs of 185 psi by putting in new piston and rings and honing cylinder and shaving down cylinder head further;

5. Open up small exhaust port and intake port on cylinder;

6. Try an SHA carburetor (15.15);

7. Try a 3″ wide tire;

8. variator modifications;

9. ??? to be determined.

11/12/18 update:

We ended up changing the order and went with a smaller main jet on the Express SR as our first modification under new ownership. If you go too small on the main jet, you can damage your piston, rings and cylinder which will require a replacement of the piston and rings and a cylinder hone. You have been forewarned. I had a 75 main jet and we installed a 70 main jet. Karl’s initial benchmark was 31.0 mph. After re-jetting, he achieved 36.4 mph on the same course. I think we should try a 65 main jet next.

Results after re-jetting.

11/16/18 update:

My buddy did another run with a 65 main jet in the Honda Express SR. He lost about 1 mph as his top speed was 35.6 mph but he reported that it ran and accelerated much better. We have since but the old 2.75″ x 10″ tire back on and will reverse the stock belt and see where that puts us. I predict that we will hit 40 mph+ down his chosen test track. From there, we can experiment with a larger carburetor, exhaust porting, piston modifications, etc., to see where we end up on the stock engine.

12/3/18 update:

We put the old tire on the rear (went from 3.5″ to 2.75″) and flipped the stock belt. He hit 36.6mph on the downhill course but, more importantly, 34mph on the flat.

12/7/2018 – Honda Express SR first heat cycle video after new piston and rings and exhaust porting

We did some exhaust porting by raising the exhaust 1.6mm on the Honda Express SR. While we were at it, we replaced the piston and rings. Here it is on its first heat cycle. I’ve got it idling high because it was so cold out at the time. It acts like it is too rich as I had to turn the idle mixture screw out to 2 full turns from 3/4 of a turn, and it loads up on fuel when I give it throttle. It wants to bog out and die when I release the throttle. I assume the rings are just doing a much better job sealing the cylinder now. I will probably drop down to a 60 main jet. Slight exhaust leak and oil pump seal leak but I’ll fix that later.

12/12/18 update: We’ve got a new exhaust on and are using a 75 main jet (which is too rich). We’ll try a 70 and then a 65 if necessary. We also replaced the rear brakes. Be careful what you order on ebay – or – you may not get what you ordered on ebay. Seller sent us front brake shoes instead of rear ones. Here’s the new exhaust:

1/6/19 update: We put the old tecno boss exhaust back on because we were trying to isolate why it kept cutting out. Well, it kept cutting out and dying with the tecno boss exhaust so I posted on moped army for some help:

“Anyhow, I’ve been helping a friend with his Express SR. In the quest for performance, things went south. I got it running and it ran pretty well. We added a somewhat better than stock exhaust – a tecno boss pipe. Ran well with that. We decided to raise the exhaust port. So we did so 1.6mm. Went ahead and replaced the piston and rings and honed the cylinder. I had to go with 2 base gaskets to seal up an air leak so I guess that pushed the cylinder up a tiny bit. Compression is 130 with those two base gaskets.

I heat cycled it 5 times and had trouble keeping it running because previous owner had removed the auto choke system. After I got sick of screwing with keeping it running for the heat cycles, I put the auto choke system back on. It still required too much monkeying around with carb settings to get it to idle right so I popped on another stock carb which seemed to help.

took it out on several break in rides and finally got it to run ok on the last couple. Now it wants to die under load and at full throttle. We’ve tried 65, 70 and 75 main jets (65 is stock on this bike) without any real changes. Could the crankshaft seals have just taken a complete and sudden dump? Damn thing!”

And then we got it running with the 85 jet. Thinking it needed more main jet, we went to a 92 but now I’m of the opinion that somewhere between a 75 and 85 jet is necessary. Stay tuned.

1/14/2019 update.

Performance tuning a small 2 stroke engine will sometimes separate the men from the boys. This Honda Express SR has been driving us crazy. It still cuts out under load at full throttle. It must have an air leak somewhere. The carburetor bolt holes were stripped, and I’m assuming that the crankshaft bearing seals are shot. So I’ve replaced the seals:

Here’s the left side seal. You have to pull a gear off the crankshaft in order to remove the old seal and pop in a new one. I tried four different pullers and a propane torch and finally got it off. I replaced the right side as well. I use Yamabond on the outside of the seals to lock it in place. It may make removal a little more difficult but I’m sure it helps keep the air out of the engine.

Here are the old seals. The right side had walked further in towards the engine and was no longer flush with its mounting space. It was difficult to pull out as a result but I’m sure it was not sealing properly. The left side seal came out too easily. It was flush with its mounting space but I’m sure it wasn’t sealing well either.

Here’s the gear on the left side that was a bear to pull out. To get it back on, I heated it in a toaster oven at 350F for 30 minutes or so. It just slides on after that.

I also installed the revolution carburetor since the stock carb’s bolt holes were stripped and the carb probably wasn’t sealing well against the intake. I came up with a little trick to deal with the extra throttle cable. For some reason, Honda used a super long curved tube on top of the chamber cab. When you replace the stock carb, you’re left with way too much bare cable. I’ll post pictures soon.

Express SR with Proma Pipe. Low and mid range are great but not much improvement on top end. Maybe slightly over-jetted. May need to throw on the BX27 belt. That will be our next move.

We are now running the Revolution Carburetor on the NX50. Here’s a picture of it installed. Honda used a funky, long tube on the stock carb that is part of the slide chamber cap. To install the Revolution Carb, I substituted a piece of old, hard fuel line to take up the slack left by the stock chamber cap tube.

Here’s the Express SR with plastics installed – FINALLY – or at least most of the plastics installed. We didn’t have them all. But looks 100% better! We tried the BX27 belt but it was still too much for a stock engine. I’m going to try a thinner belt and let that engine/proma combination rev a bit more.

New Dellorto SHA clone carb and just painted Proma type exhaust.

3-14-2019 – Update: So we have the SHA clone carb installed with a 71 main jet. We went back to the stock belt flipped inside out. On a hunch that we weren’t in the power band when the bike shifts (I’ll call it shifting from first to second gear at around 18-20 mph), we went from 36 grams in the variator to 31.5 grams. The idea was to make it rev out higher prior to the shift from first to second gear and then when it shifted to second – the rpms wouldn’t drop so much and we would still be in the power band in second gear. Previously, the rpms would drop too low and you’d have to spend forever in second gear to get them back up to in or near the power band.

Results – we hit 35.9mph on the flat – no slight downhill this time for testing. This is our best result to date. Our next move is to lower the weights in the variator further because the bike seems to still be shifting to easy from first to second gear (again this is my terminology and not technically correct). Maybe we go to 27 grams next. We want to make the bike struggle a little before shifting from first to second. By struggling, the bike will have to reach higher rpms to make the shift. When it makes the shift, the plan is that rpms drop but are still in the power band.

Other moves include maybe dropping to a 69 jet and maybe trying the spacer trick that I outline in one of my youtube videos. We shall see. Stay tuned!

5-16-2019 update – I think we are back at 33 grams in the variator and we may still have the 71 main jet. Our latest thought is that we need to go back to the huge rear tire. Seems like the rpms are real high at top speed but we are limited by the belt and/or small rear tire. The stock belt flipped inside out has been the best performer so far. That just leaves going back to the big back tire. I think the engine with the help of the proma pipe has the power to turn that big back tire now. Will update soon.

10/28/20- I think know the proma pipe is just not a top end pipe. Acceleration is great with the proma but it peaks way too early. To get 36 or whatever with that pipe was pretty damn good. I’ve since obtained another SR and the quest continues.