This article won’t be a step-by-step how to but will give you the basics on how to install a new and larger top end on your Yamaha qt50 (also infamously known as the big bore kit).

Video on replacing left crank shaft bearing seal

If you don’t know the maintenance history of your qt50, you will want to change the left and right crankshaft seals before doing anything related to your top end. You will need a piston stop and a flywheel puller.

Those seals are 35-40 years old and if they are not sealing correctly, they will allow air to leak past and into the engine. This extra air will make your engine run hot, overheat and ruin your new top end. In addition, bad seals will make jetting a nightmare later. You will never be able to get it jetted right. I’ve linked to everything you need so no excuses – just do it. Trust me, I’ve made this mistake and learned the hard way.

You might say, “Well, my qt50 runs fine without the big bore kit. Why should I change the seals?” Your big bore kit will run at a much higher rpm than the stock top end. Running at a higher rpm, it will run hotter. Also, running at a higher rpm, any leaks in the seals will be magnified. Your engine will pull in more air through bad seals with a big bore kit. It will eventually overheat and seize.

Why bad crank shaft bearing seals can cause problems

Beyond that, you should make sure your qt50 is running great before installing a new top end. A bigger engine will tend to exaggerate any issues you haven’t taken care of prior to install. See above – a bigger top end will exaggerate the amount of air coming in through bad seals, for example.

Here’s a great article on installing a kit. I’ll add a few things below for a little extra guidance.

IF YOUR BIKE WON’T START AFTER INSTALLING A BIGGER TOP END KIT, YOU MAY NEED TO REPLACE THE CHARGE COIL ON THE STATOR!

1. Get your qt50 off the ground! I tried to install my first kit with my qt50 on the ground. What a pain! I’ve since learned otherwise. Get it up on a workbench so you can stand up and do this right. Heck, you can find a cheap folding table on Craigslist which will do the job. Or an old office desk or get a couple sawhorses and a long piece of plywood.

Corollaries to this rule are employ good lighting and try to do the work in your garage or inside somewhere. During portions of a kit install, you are dealing with really small parts. Good lighting is a necessity. Believe me when that circlip flies across the room, you’ll need excellent lighting to find it. If you can do the work indoors, this will allow you to stop and come back to it later if necessary.

Don’t be in a hurry to ride either. Take your time and do this right so you don’t have to do it again.

2. The broom trick. The broom trick occurs in two stages. First, sweep the floor of your work space really well. Then have the broom handy when your circlip shoots away from you. You will be sweeping the floor again to find it. Echolocation also helps in finding your lost circlip.

3. Needle-nose pliers. You will need a small pair of needle-nose pliers to install the circlips. Better yet, pick up a set of them in different flavors.

4. Check the gap on your rings and make sure it is within specs. If the gap is too small, sand the ends of the rings lightly with sandpaper to increase the gap. A few gentle strokes on each end is all you need. Take each ring and place it in your cylinder and then press it down 1/2″ or so with the piston to center it. Measure your ring gap again with a feeler gauge. If you are really cautious, then measure the ring gap at different places in the cylinder as well. Here’s a great article on what your ring gap should be depending on what size kit you are installing.

5. Cylinder ports have sharp edges. You will most likely want to chamfer the edges with a Dremel or a file or wrap some fine grit sandpaper around a chopstick. Basically you don’t want your rings to get hung up by sharp edges in the cylinder. Make sure to clean your cylinder very carefully after doing this. ScooterSwapShop has a great video on chamfering ports.

6. Install the rings on right. Rings are brittle. They will break. Ease one on gently into the first groove. Ease it out and ease it into the second groove little by little. In fact, you may want to practice once or twice with your old rings on your old piston if you’ve never done this before. Better to break an old ring than a new one. Qt50 rings are interchangeable so it doesn’t matter which goes on top or bottom; however, the ring only goes on one way. The small letters go towards the top or dome of the piston. If you put them on backwards, you will know because the piston and rings will not slide into the cylinder without the aid of a mallet. Another way to check is that the ring ends will fit under the ring stop.

7. Circlip installation is hell but get it right. Yamaha qt50 circlips aren’t too bad. They are shaped like a “G”. Grap the straight arm of the “G” with your pliers. Insert circlip at an angle and get the top of it in the groove. Twist and spin the circlip around and pull it entirely into the groove. You may have to take your other hand and push the circlip in as you spin it with the needle nose pliers. The straight part of the circlip must be parallel to the piston’s direction of travel (consult pictures in link above for installing a kit). Something I didn’t know – “some circlips have a machined flat side which faces inward”. I don’t think qt50 circlips do. Install one circlip on the piston before you install the piston on the crankshaft arm.

8. Install the piston correctly. The arrow on the piston points down at the exhaust. The ends of the rings rest against the ring stop. Align these before attempting to put the cylinder over the piston. Keep them aligned during install. You can install the piston on the crankshaft arm before fitting the cylinder over the piston. Or you can partially install the piston in the crankshaft and then put the piston/cylinder on the crankshaft arm. An extra set of hands here is helpful. Smear some two stroke oil inside the cylinder and on the piston before you put the piston in the cylinder.

8.5. Get a new head gasket, base gasket and exhaust gasket. Smear two stroke oil on each side of the base gasket so it will be easy to remove next time someone takes off the top end.

9. Get an inch/pound torque wrench to properly torque your cylinder head nuts to 84 inch/lbs.

10. Properly break in your kit so that it lasts. The linked article is probably overkill but I found that one of the biggest advantages of heat cycling your engine five times is that you can nip problems in the bud. Pay attention to your temperature gauge and to the engine while it is heat cycling. Is it belching a lot of smoke? Is it idling higher than it should? Does the temperature finally level off and drop a little when it is fully warmed up? Pay attention while you take it through the break-in rides as well. The long break-in process provides you with plenty of opportunities to catch and fix problems before they become nightmares.

11. A cylinder head temperature gauge is helpful but not foolproof.

12. Go ahead and remove the engine side covers and the footpegs so you have easier access to the top end. If you want, it’s not too hard to take the frame off the engine. This will make working on the engine much easier.

13. After installing your top end, put a bigger main jet in your carburetor. If the 60cc kit is all that you have done and everything else is stock, then try a 77.5 jet. That should get you real close. If you’ve added a performance exhaust and/or a really high flow air filter, then start around 85 for the main jet. Or better yet, get a bigger carburetor.

14. PROPERLY BREAK IN YOUR KIT AS MENTIONED ABOVE. Even after the initial break in, allow your engine to warm up fully before blasting. A temp gauge is handy for this.

15. I really believe in fuel/oil mixtures of 40:1 or so, especially with a kit. Forget that 80:1 bullshit! The higher rpms you turn, the more oil you need.

IF YOUR BIKE WON’T START AFTER INSTALLING A BIGGER TOP END KIT, YOU MAY NEED TO REPLACE THE CHARGE COIL ON THE STATOR!

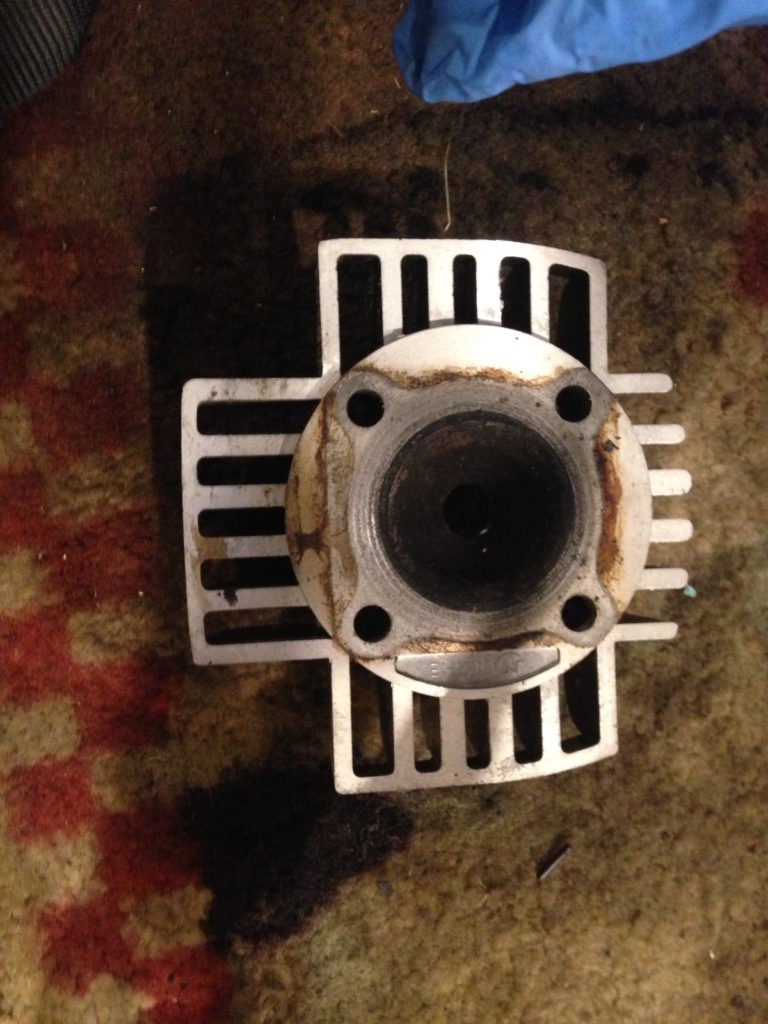

16. See this cylinder head. Fuel leaked around the head gasket. You can tell by looking at it. This means your cylinder head, cylinder or both were not level/flat. They can be a little off and the head gasket will generally take care of it but, in this case, it did not. If it leaks fuel then air is leaking in and causing your engine to run too hot. You can sand down the cylinder head but if the cylinder’s mating surface is not flat/level, it will have to be machined down. Doing so is probably not worth the time, effort and money. Get a better kit instead.

17. You’ve installed the kit. Now, how do you get it to perform its best.

Install the pw50 gears or your bike will rev to the moon just to maybe hit 45 or so. Upgrade your tires and brakes. Consider adding a crossbar for more stability while riding. Orange clutch springs will help restore low end. Always run a decent quality 2 stroke oil with a high flash point and high viscosity.